MMI is an expert provider of prototypes and small to medium production runs of custom products, providing hardware and software solutions for a wide variety of custom applications.

All of our work is based on interactive relationships with our customers throughout design, development, and manufacturing, to provide a realistic solution for each customer's ideas. Our goal is to provide solutions within the customers operating parameters and budget.

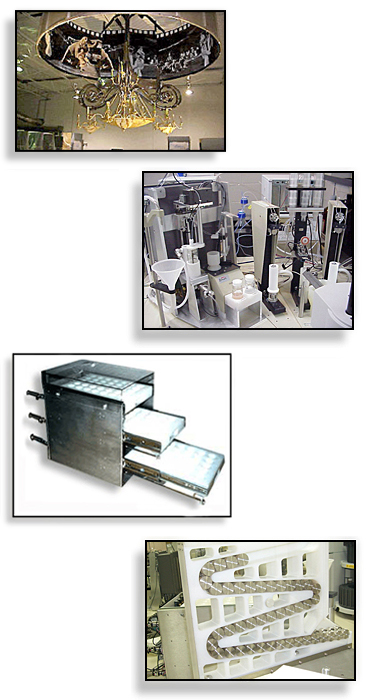

Prototypes

Prototypes

We develop and produce working prototypes that fulfill our customer's needs. And we maintain a close interactive relationship with our customer throughout the entire process so that the customer's needs are efficiently and effectively met, on time and within budget.

Experience

Experience

The extensive knowledge and experience of the MMI staff with mechanical systems, electronics, sensors, PLCs, hydraulics, and pneumatics/vacuum systems is invaluable in the design and manufacturing of a project.

CAD (Computer Aided Design)

CAD (Computer Aided Design)

To reach our goal of providing cost-effective solutions for our customers, we utilize MMI internal and out-sourced services. Working with AutoCAD and SolidWorks software, we can provide prototype design/engineering and programming.

MMI can create designs based on a customer's idea, we can enhance a customer's conceptual rendering, or we can convert customer engineered drawings into a finished project.

Fabrication

Fabrication

MMI shop personnel are skilled at producing parts that require cutting, forming, and machining, or punching, bending, and finishing. These parts, produced to tight tolerances, are then assembled with purchased/modified components and integrated with electronic systems that can communicate upstream and downstream with existing customer systems. Design and production of control panels, along with associated wiring, completes a project.

Surface Finishing

Surface Finishing

Each project is delivered ready for use, with surface finishes on fabricated parts that might be anodized, powdercoated, painted, or with an omni-directional or brushed finish. Our equipment can apply a brushed finish to material up to 50" wide in thicknesses up to 8".